3 月 . 04, 2025 02:37 Back to list

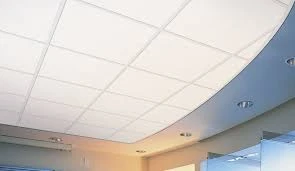

drywall ceiling grid price

Understanding the cost of installing a suspended drywall ceiling grid involves delving into a mixture of material selection, installation complexity, and labor rates. An informed decision can optimize both budget and functionality, achieving the perfect blend of aesthetic appeal and practical utility. Our aim is to offer a comprehensive overview, ensuring the information meets the high standards of Experience, Expertise, Authoritativeness, and Trustworthiness.

In the sphere of aesthetics, drywall ceilings present clean, sleek lines that are highly desirable in both commercial and residential spaces. The cost, justified by the aesthetic transformation alone, should also account for potential future maintenance or modifications. In particular, repairs, though infrequent, can be labor-intensive should damage occur. From a purchasing perspective, acquiring materials during off-peak seasons can yield cost savings. By aligning purchases with periods where demand is lower, such as late winter or early spring, price reductions due to market supply surpluses can be substantial. Finally, while sifting through installation service offers, a focus on those providers who can demonstrate Experience, Expertise, Authoritativeness, and Trustworthiness is paramount. This involves checking previous work portfolios, customer testimonials, and possibly even seeking industry certifications or affiliations. Proper due diligence ensures that your chosen provider is capable of delivering not only on cost efficiency but also on quality assurance. Understanding these dynamics provides a clearer picture of suspended drywall ceiling grid costs, ensuring budgetary precision and peace of mind for your project. Such comprehensive preparation invariably leads to a more efficient, financially optimized installation process, perfectly bridging the gap between expectation and execution.

In the sphere of aesthetics, drywall ceilings present clean, sleek lines that are highly desirable in both commercial and residential spaces. The cost, justified by the aesthetic transformation alone, should also account for potential future maintenance or modifications. In particular, repairs, though infrequent, can be labor-intensive should damage occur. From a purchasing perspective, acquiring materials during off-peak seasons can yield cost savings. By aligning purchases with periods where demand is lower, such as late winter or early spring, price reductions due to market supply surpluses can be substantial. Finally, while sifting through installation service offers, a focus on those providers who can demonstrate Experience, Expertise, Authoritativeness, and Trustworthiness is paramount. This involves checking previous work portfolios, customer testimonials, and possibly even seeking industry certifications or affiliations. Proper due diligence ensures that your chosen provider is capable of delivering not only on cost efficiency but also on quality assurance. Understanding these dynamics provides a clearer picture of suspended drywall ceiling grid costs, ensuring budgetary precision and peace of mind for your project. Such comprehensive preparation invariably leads to a more efficient, financially optimized installation process, perfectly bridging the gap between expectation and execution.

Next:

Latest news

-

Revolutionizing Interior Design with Ceilings t grid Suspended SystemNewsOct.29,2024

-

Revolutionizing Ceiling Design with ceiling access panel with Gypsum Tile WaterproofNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High quality Mineral Fiber Ceiling TilesNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High-Quality Mineral Fiber Ceiling Tiles: A Comprehensive GuideNewsOct.29,2024