5 月 . 30, 2025 12:52 Back to list

Suspended Ceiling Grid Types & Tile Varieties Modern & Durable

- Introduction to Suspended Ceiling Grid Systems

- Technical Advantages of Modern Grid Systems

- Overview of Main Grid Types

- Comparative Analysis: Leading Manufacturers

- Types of Ceiling Tiles for Suspended Ceilings

- Custom Solutions for Unique Requirements

- Application Case Studies

(suspended ceiling grid types)

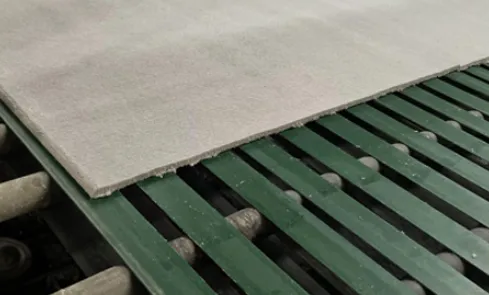

Understanding Suspended Ceiling Grid Types

Suspended ceiling grids form the backbone of modern interior architecture, supporting various panel configurations across commercial and residential spaces. Industry data shows this market segment growing at 7.2% CAGR globally, driven by increasing construction in healthcare and education sectors requiring versatile overhead solutions. The choice between suspended ceiling grid types

impacts installation efficiency, acoustics, and visual harmony in a space. These aluminum or steel frameworks work like invisible skeletons, typically featuring interlocking tee-bars creating consistent geometric patterns that conceal structural elements while granting maintenance access to mechanical systems above. Their standardized sizing allows for remarkable design flexibility across diverse projects.

Technical Advantages of Modern Grid Systems

Contemporary grid systems deliver substantial functional improvements. Structural innovations like heavier gauge metals and reinforced junction points enable 25% longer span capabilities compared to legacy systems, reducing material requirements. Cruciform connection systems installed 40% faster than traditional clip models while improving seismic resistance. Major enhancements include precision laser-notched profiles ensuring perfect 90-degree intersections and integrated seismic bracing options that meet ASCE 7-16 standards. Additional benefits include thermal-break designs minimizing condensation risks and acoustically-enhanced channels that reduce structure-borne noise transmission by up to 26dB. These performance gains create significant value through lower installation costs and extended service life.

Overview of Main Grid Types

Four primary configuration categories serve different architectural requirements. Standard 15/16-inch exposed grids represent the dominant commercial solution, supporting all common panel types in modular designs. For premium spaces, narrow-profile 9/16-inch systems create refined visual lines while accommodating 2'x4' or 2'x2' panels. Specialty options include concealed clip-in grids offering seamless plane illusions and access-oriented designs with removable cross-tees for frequent above-ceiling servicing. Materials range from economical painted steel weighing 1.5lbs/ft to premium architectural-grade aluminum at 0.8lbs/ft with enhanced corrosion resistance. Each configuration serves distinct functions from utility basements requiring high accessibility to designer lobbies demanding minimal visual interruption.

Comparative Analysis of Suspended Grid Manufacturers

The market features distinct quality tiers addressing varied project needs. Leading manufacturers compete through specialized design innovations and regional supply chains.

| Manufacturer | Product Series | Materials | Design Features | Warranty |

|---|---|---|---|---|

| Armstrong World Industries | Ultima & Prelude | Pre-galvanized steel, 6000-Series aluminum | Seismic Performance Category D, AcoustiLock splines | 30-year limited |

| USG Corporation | DX System & Donn | Cold-rolled steel, AL-7 aluminum | SnapLock connections, Fire-Rated options | Lifetime structural |

| CertainTeed | Cascade & Solarflex | G90 galvanized steel, Mill-finished aluminum | Torsion Spring tees, Moisture-resistant finishes | 25-year limited |

| Chicago Metallic | Centria & 800 Series | 6063-T5 aluminum, Hot-dipped zinc steel | Perimeter-free designs, ColorMatch finishes | 20-year finish warranty |

Exploring Ceiling Tiles for Suspended Grids

Complementing grid frameworks, diverse tile technologies optimize environmental performance across settings. Mineral fiber panels remain dominant at 62% market share due to excellent acoustic absorption (NRC up to 0.95) and UL fire-resistant classifications. Metal options including micro-perforated aluminum deliver superior humidity resistance for kitchens and pools, while rigid vinyl tiles serve sterile environments like laboratories with seamless cleanability. Architects increasingly specify specialty tiles such as impact-resistant PET felt panels (up to 98% recycled content) and molded wood fiber acoustics that achieve 37dB CAC ratings. Each category offers specific technical advantages from MRI-friendly non-metallic boards to mold-resistant coated tiles providing Class A moisture protection in challenging environments.

Customized Grid Solutions

Project-specific challenges necessitate engineered modifications. Integrated ventilation grids embed linear diffusers directly into the assembly maintaining ceiling plane continuity while delivering 30% more uniform airflow distribution. In conservation settings, custom anodized aluminum finishes replicate historic elements while meeting structural code requirements. For high-vibration environments like recording studios, manufacturers create hybrid systems with rubber-isolated grid hangers preventing flanking noise transmission. Complex geometric layouts often use digitally-fabricated components with angled connectors adapting to curved planes. Customization extends to fire-protection systems where proprietary fire-rated assemblies achieve up to 2-hour ratings in steel deck constructions, meeting increasingly stringent building codes for multi-story commercial projects.

Applications Where Suspended Ceiling Solutions Excel

Healthcare projects underscore system versatility with specialized suspended ceiling grid types. Recent hospital installations demonstrate hybrid systems coordinating medical gases, radiation shielding, and rigorous infection control. Emergency department retrofits showcase rapid-grid deployment technologies enabling weekend installations without disrupting critical services. Educational projects increasingly leverage grid systems featuring impact-resistant panels in athletic facilities while integrating cloud-like acoustic baffles in lecture halls. Commercial offices reveal growing adoption of demountable partitions coupled with suspended systems to create flexible workspaces adapting to organizational changes. Hospitality venues use suspended structures for dramatic lighting integration and easy service access behind bars and kitchens. Each sector benefits from precisely selected grid configurations maximizing both function and aesthetics.

(suspended ceiling grid types)

FAQS on suspended ceiling grid types

Q: What are the common types of suspended ceiling grid systems?

A: Common suspended ceiling grid types include standard "T-grid" systems, narrow-profile grids for sleek designs, and heavy-duty grids for commercial spaces. Materials range from aluminum to galvanized steel, depending on load and durability needs.

Q: What materials are used for suspended ceiling grid frameworks?

A: Suspended ceiling grids are typically made of aluminum, steel, or vinyl. Aluminum is lightweight and corrosion-resistant, while steel grids offer higher strength for heavy ceiling tiles or HVAC components.

Q: How do I choose the right grid type for my suspended ceiling?

A: Consider tile size, weight, and room usage. Standard 15/16" grids suit most tiles, while 9/16" narrow grids work with lightweight tiles. Heavy-duty grids are ideal for commercial spaces with frequent access needs.

Q: What types of ceiling tiles work with suspended grid systems?

A: Common tiles include mineral fiber (acoustic), metal, wood, and PVC. Tile sizes (e.g., 2'x2' or 2'x4') must match the grid layout, and edge profiles (tegular or square) affect aesthetics and light reflection.

Q: Are fire-rated ceiling tiles compatible with all suspended grid types?

A: Fire-rated tiles require grids with matching fire resistance, often steel-based. Always verify local building codes and ensure grid components (splines, hangers) meet the same fire-rating standards as the tiles.

-

Revolutionizing Interior Design with Ceilings t grid Suspended SystemNewsOct.29,2024

-

Revolutionizing Ceiling Design with ceiling access panel with Gypsum Tile WaterproofNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High quality Mineral Fiber Ceiling TilesNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High-Quality Mineral Fiber Ceiling Tiles: A Comprehensive GuideNewsOct.29,2024