2 月 . 15, 2025 20:45 Back to list

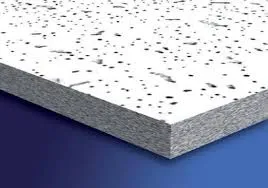

surface mount grid system

Navigating the intricacies of electronics design often requires precision and adaptability. Among the myriad solutions available, the surface mount grid system distinctly elevates the standards for electronic assembly processes. This advanced system is not merely a technological marvel but a blueprint for innovation, performance, and reliability in the electronics manufacturing industry.

In terms of durability and reliability, the surface mount grid system offers robust solutions capable of withstanding harsh operating environments. The surface-mount technology (SMT) employed results in stronger mechanical bonds and better resistance to vibrations and impact. This robustness is crucial for industries where operational integrity is non-negotiable, such as aerospace and defense. Expertise in deploying such an advanced system comes from understanding its implications on thermal and electrical performance. An experienced engineer knows that while the compactness of SMT components promotes efficient use of space, it also demands meticulous thermal management to prevent overheating and ensure longevity of components. Utilizing advanced thermal simulation tools can help anticipate and mitigate potential heat-related issues, optimizing performance. Authoritativeness in leveraging a surface mount grid system is built through adherence to industry standards and continuous learning. Standards like IPC-610 guide the quality control processes, ensuring that each PCB assembly meets rigorous quality criteria. Participation in ongoing training programs and industry conferences helps professionals stay abreast of emerging trends and technologies that can further enhance the capability of these systems. Trustworthiness is the final cornerstone of capitalizing on a surface mount grid system. Clients and stakeholders must have confidence not just in the technology but in the team implementing it. Building this trust requires transparent processes, clear communication regarding capabilities and limitations, and delivering consistent results that meet or exceed client expectations. In conclusion, the surface mount grid system is more than a technological advancement; it is a transformative approach to modern electronics manufacturing. Through its efficiency, versatility, and capability to accommodate high-density and robust applications, it establishes a new paradigm in hardware design. With the right expertise and adherence to industry standards, this system is a powerful tool that can propel businesses ahead in a competitive global market.

In terms of durability and reliability, the surface mount grid system offers robust solutions capable of withstanding harsh operating environments. The surface-mount technology (SMT) employed results in stronger mechanical bonds and better resistance to vibrations and impact. This robustness is crucial for industries where operational integrity is non-negotiable, such as aerospace and defense. Expertise in deploying such an advanced system comes from understanding its implications on thermal and electrical performance. An experienced engineer knows that while the compactness of SMT components promotes efficient use of space, it also demands meticulous thermal management to prevent overheating and ensure longevity of components. Utilizing advanced thermal simulation tools can help anticipate and mitigate potential heat-related issues, optimizing performance. Authoritativeness in leveraging a surface mount grid system is built through adherence to industry standards and continuous learning. Standards like IPC-610 guide the quality control processes, ensuring that each PCB assembly meets rigorous quality criteria. Participation in ongoing training programs and industry conferences helps professionals stay abreast of emerging trends and technologies that can further enhance the capability of these systems. Trustworthiness is the final cornerstone of capitalizing on a surface mount grid system. Clients and stakeholders must have confidence not just in the technology but in the team implementing it. Building this trust requires transparent processes, clear communication regarding capabilities and limitations, and delivering consistent results that meet or exceed client expectations. In conclusion, the surface mount grid system is more than a technological advancement; it is a transformative approach to modern electronics manufacturing. Through its efficiency, versatility, and capability to accommodate high-density and robust applications, it establishes a new paradigm in hardware design. With the right expertise and adherence to industry standards, this system is a powerful tool that can propel businesses ahead in a competitive global market.

Latest news

-

Revolutionizing Interior Design with Ceilings t grid Suspended SystemNewsOct.29,2024

-

Revolutionizing Ceiling Design with ceiling access panel with Gypsum Tile WaterproofNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High quality Mineral Fiber Ceiling TilesNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High-Quality Mineral Fiber Ceiling Tiles: A Comprehensive GuideNewsOct.29,2024