2 月 . 19, 2025 11:16 Back to list

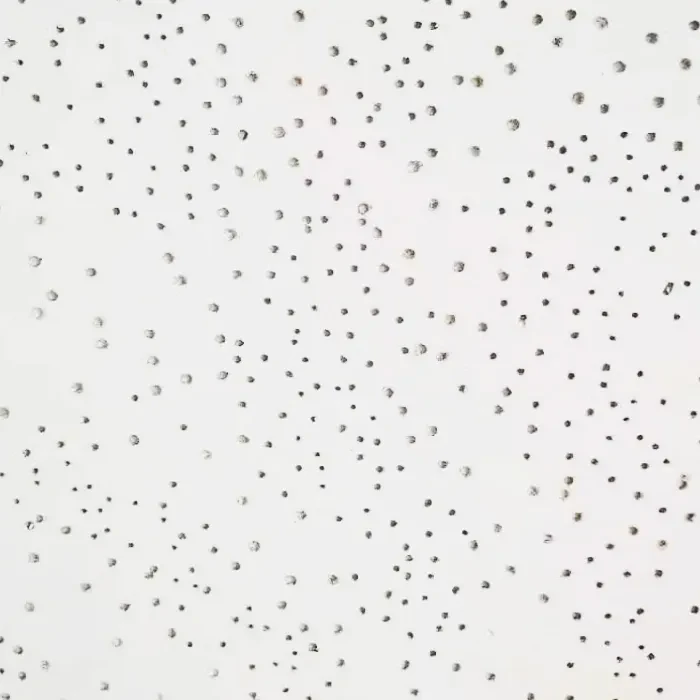

PVC Gypsum Ceiling

PVC laminated gypsum boards have become a staple in modern construction, offering a seamless blend of durability and aesthetic appeal. These boards are particularly favored for their versatility in both residential and commercial settings. However, one of the most frequent considerations for builders and homeowners alike is the cost associated with these boards. Understanding the price factors and acquiring tips from industry experts can greatly aid in making an informed purchase decision.

Furthermore, geographic location can impact the price of PVC laminated gypsum boards. Proximity to manufacturing facilities can reduce transportation costs, thereby lowering the price. Conversely, importing boards from other regions may incur additional shipping costs, affecting overall expenses. Local market rates and demand also play a role; regions experiencing construction booms might see fluctuations in board prices due to heightened demand. Having insights from industry experts can be invaluable. Consultation with experienced contractors or suppliers can provide guidance tailored to specific project requirements, helping to avoid over-specification or underutilization of board properties. These professionals can offer recommendations on the most suitable boards for particular environments, balancing cost against performance effectively. Trustworthiness in the construction industry is built on transparency and adherence to quality standards. Reputable suppliers provide certifications and evidence of compliance with international standards for quality and safety. Verifying these credentials is crucial in ensuring the authenticity of claims made by suppliers regarding product features and benefits. Buyers should prioritize suppliers who are open about their sourcing, manufacturing processes, and who provide clear product specifications. In conclusion, while the price of PVC laminated gypsum boards is a key consideration in the decision-making process, it should be evaluated in the context of quality, durability, and overall project needs. Selecting the appropriate boards involves balancing initial costs with long-term benefits, considering factors such as manufacturing quality, additional features, and reliable supplier practices. Through informed decision-making and expert consultation, buyers can achieve optimal results, ensuring both cost-efficiency and high-performance building solutions.

Furthermore, geographic location can impact the price of PVC laminated gypsum boards. Proximity to manufacturing facilities can reduce transportation costs, thereby lowering the price. Conversely, importing boards from other regions may incur additional shipping costs, affecting overall expenses. Local market rates and demand also play a role; regions experiencing construction booms might see fluctuations in board prices due to heightened demand. Having insights from industry experts can be invaluable. Consultation with experienced contractors or suppliers can provide guidance tailored to specific project requirements, helping to avoid over-specification or underutilization of board properties. These professionals can offer recommendations on the most suitable boards for particular environments, balancing cost against performance effectively. Trustworthiness in the construction industry is built on transparency and adherence to quality standards. Reputable suppliers provide certifications and evidence of compliance with international standards for quality and safety. Verifying these credentials is crucial in ensuring the authenticity of claims made by suppliers regarding product features and benefits. Buyers should prioritize suppliers who are open about their sourcing, manufacturing processes, and who provide clear product specifications. In conclusion, while the price of PVC laminated gypsum boards is a key consideration in the decision-making process, it should be evaluated in the context of quality, durability, and overall project needs. Selecting the appropriate boards involves balancing initial costs with long-term benefits, considering factors such as manufacturing quality, additional features, and reliable supplier practices. Through informed decision-making and expert consultation, buyers can achieve optimal results, ensuring both cost-efficiency and high-performance building solutions.

Next:

Latest news

-

Revolutionizing Interior Design with Ceilings t grid Suspended SystemNewsOct.29,2024

-

Revolutionizing Ceiling Design with ceiling access panel with Gypsum Tile WaterproofNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High quality Mineral Fiber Ceiling TilesNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High-Quality Mineral Fiber Ceiling Tiles: A Comprehensive GuideNewsOct.29,2024