6 月 . 10, 2025 15:20 Back to list

Premium PVC False Ceiling Tiles – Durable, Waterproof Panels for Modern Interiors

- Introduction: Embracing Modern Design with PVC False Ceiling Tiles

- Understanding Material and Technical Superiority

- Comparative Manufacturer Analysis

- Customization and Design Flexibility

- Application Scenarios and Case Studies

- Installation and Maintenance Insights

- Conclusion: The Future of PVC False Ceiling Tiles

(pvc false ceiling tiles)

Introduction: Unlocking Possibilities with PVC False Ceiling Tiles

The pursuit of advanced interior aesthetics and optimized utility in contemporary architecture has paved the way for innovative solutions such as PVC false ceiling tiles. Offering a seamless blend of form and function, these tiles have become integral in residential, commercial, and institutional settings. With an annual global market value surpassing $1.3 billion in 2023 and a projected compound annual growth rate of 6.7% through 2029, the adoption rates of PVC-based ceiling solutions are outpacing traditional gypsum and mineral fiber panels. This surge is driven by their outstanding versatility, durability, and ease of installation. As the demand for modern interior design evolves, understanding the advantages and applications of PVC false ceiling solutions becomes imperative for architects, contractors, and property owners alike.

Technical Advantages: PVC False Ceiling Tiles and Panels

The technical attributes of PVC false ceiling tiles and PVC false ceiling panels position them ahead of older alternatives like metal and asbestos-based tiles. These products are manufactured using high-grade polyvinyl chloride, rendering them inherently resistant to moisture, corrosion, and termite infiltration. The standard moisture resistance rating exceeds 95% relative humidity, making them suitable for high-moisture environments like kitchens, spas, and laundromats.

In terms of fire safety, most PVC ceiling tiles conform to Class B-s1,d0 of the EN 13501-1 fire resistance standard. Structurally, their acoustic insulation properties are noteworthy, with a noise reduction coefficient (NRC) of up to 0.60. The lightweight property, averaging 3.5–4.2 kg/m², enables faster installation without requiring reinforced ceiling grids. Also, unlike gypsum panels that are susceptible to water absorption and cracking, PVC tiles retain their form and aesthetic appeal over extended periods.

Manufacturer Comparison: PVC and Gyproc PVC False Ceiling Solutions

Selecting a reliable manufacturer directly impacts product longevity and aesthetic precision. The table below assesses core performance indicators among leading brands in the sector:

| Brand / Model | Material | Thickness (mm) | Weight (kg/m²) | Fire Rating | Acoustic NRC | Warranty (years) | Standard Panel Size (mm) | Customisation Options |

|---|---|---|---|---|---|---|---|---|

| Supreme Panels | PVC | 7, 8, 10 | 3.7 | B-s1,d0 | 0.55 | 10 | 600 × 600 | Colours, prints, textures |

| Gyproc PVC Plus | Gypsum + PVC lamination | 8, 12 | 5.5 | B-s1,d0 | 0.62 | 8 | 595 × 595 | Edge profile, finish |

| EcoCeil Decor | PVC | 6, 8 | 3.5 | B-s1,d0 | 0.58 | 7 | 610 × 610 | UV print, 3D relief |

| PlastiCeil Ultra | PVC | 5, 7 | 3.9 | B-s1,d0 | 0.53 | 9 | 600 × 1200 | Patterns, modular forms |

The comparison illustrates that while Gyproc’s PVC-laminated product offers superior acoustics due to gypsum’s properties, pure PVC panels like Supreme Panels and EcoCeil Decor excel in moisture resistance and customization potential.

Customization: Meeting Unique Project Demands

The flexibility in production and finishing methods for PVC false ceiling tiles empowers specifiers to realize virtually any visual theme or branding requirement. Standard sizes can be tailored in millimetre increments, with popular finishes including matte, high-gloss, wood grain, metallic, and marble effect. Large-scale commercial installations frequently request anti-bacterial and anti-fungal coatings, especially in healthcare and F&B sectors. For designers, UV-curable inks enable high-resolution graphics, corporate logos, or thematic imagery to be embedded directly into the tile surface.

For example, an international retail chain recently opted for 3000 square meters of custom graphic-printed tiles to coordinate ceiling visuals with in-store marketing campaigns. Moreover, modularity in the support grid allows for irregular or organic-shaped layouts, further expanding creative expression in interior environments.

Application Stories: Transforming Spaces with PVC Ceilings

Real-world case studies showcase the range of environments where PVC false ceiling tiles and panels create significant value. In a multi-campus university in the UK, over 13,000 m² of PVC tiles were deployed, reducing annual maintenance costs by 28% versus prior mineral fiber installations, mainly due to enhanced stain resistance and easier cleaning.

In hospitality, a regional hotel group retrofitted all guest bathrooms and kitchens with high moisture-resistant PVC panels, reporting a zero incidence of mold or water damage over five years. Similarly, a Malaysian manufacturing facility utilized Gyproc PVC false ceiling panels in their precision assembly areas, reducing particulate contamination by 18% per ISO 14644 monitoring, while also benefiting from rapid panel replacement procedures during equipment upgrades.

Installation and Maintenance: Practical Considerations

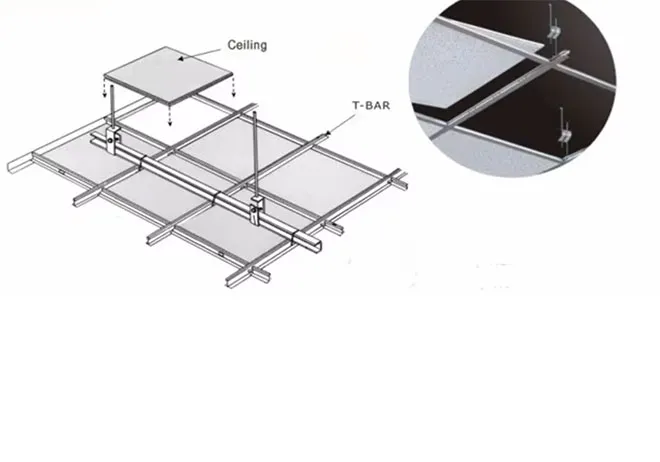

Contractors benefit from the straightforward, dust-free install process afforded by PVC tiles. The lightweight nature allows a single person to handle tiles overhead, with typical installation rates of 30–45 m² per worker per day. Panels slot securely into standard T-bar grid systems, and cutting to fit lighting appliances or HVAC diffusers can be achieved with basic site tools.

Maintenance cycles are drastically reduced: routine cleaning requires only mild detergent and non-abrasive wipes. Unlike traditional painted ceilings, there is no need for cyclical repainting, and panels are easily swapped for replacements if required. Further, the material is fully recyclable, supporting sustainability initiatives in green building projects.

Conclusion: The Future of PVC False Ceiling Tiles

In conclusion, PVC false ceiling tiles represent a robust investment for interior spaces prioritizing aesthetics, hygiene, and lifecycle efficiency. With versatile design options, high durability, and cost-effective maintenance, they are outperforming traditional solutions in an increasing range of applications. As materials technology continues to evolve and customization capabilities expand, the market share of PVC false ceiling solutions is expected to escalate significantly, shaping the architectural landscapes of tomorrow’s spaces.

(pvc false ceiling tiles)

FAQS on pvc false ceiling tiles

Q: What are PVC false ceiling tiles and how are they used?

A: PVC false ceiling tiles are lightweight decorative panels made from polyvinyl chloride. They are often installed in suspended ceiling systems for homes, offices, and commercial spaces. Their water resistance and easy installation make them a popular choice.Q: How do PVC false ceiling panels differ from traditional gypsum ceilings?

A: PVC false ceiling panels are moisture-resistant, lightweight, and easy to clean compared to traditional gypsum ceilings. They also do not crack or warp easily. Additionally, PVC panels come in various colors and patterns for enhanced aesthetics.Q: Are Gyproc PVC false ceilings durable and suitable for humid areas?

A: Yes, Gyproc PVC false ceilings are designed for durability and excellent moisture resistance. They are ideally suited for use in kitchens, bathrooms, and other humid environments. Their smooth surface makes cleaning and maintenance simple.Q: Can I install PVC false ceiling tiles by myself?

A: PVC false ceiling tiles are known for their ease of installation and can be installed by DIY enthusiasts using basic tools. However, professional installation is recommended for larger or more complex spaces. Proper alignment and support ensure long-lasting results.Q: What are the maintenance requirements for PVC false ceiling tiles?

A: PVC false ceiling tiles require minimal maintenance—simply wipe with a damp cloth to keep them clean. They do not absorb water or attract mold and mildew. Regular dusting will keep your ceiling looking new and fresh.-

Revolutionizing Interior Design with Ceilings t grid Suspended SystemNewsOct.29,2024

-

Revolutionizing Ceiling Design with ceiling access panel with Gypsum Tile WaterproofNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High quality Mineral Fiber Ceiling TilesNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High-Quality Mineral Fiber Ceiling Tiles: A Comprehensive GuideNewsOct.29,2024