1 月 . 24, 2025 01:59 Back to list

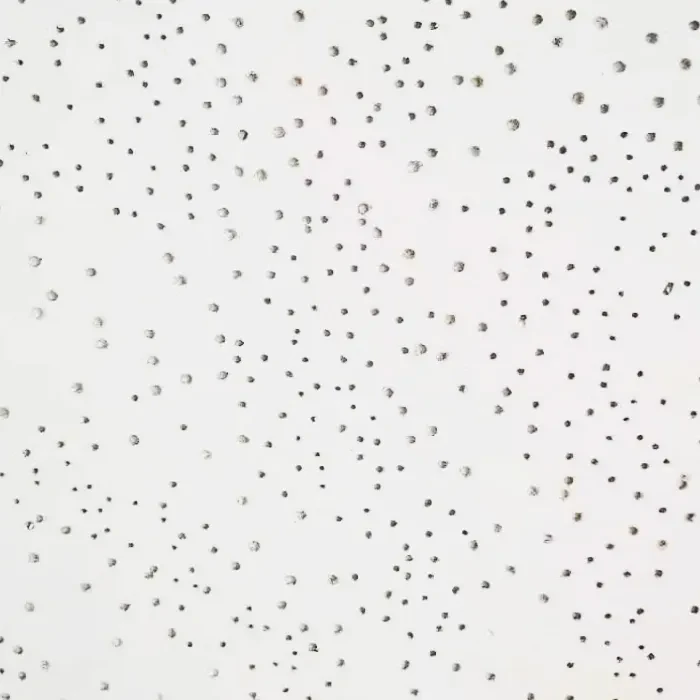

frp ceiling grid

Fiber Reinforced Plastic (FRP) ceiling grids have emerged as a preferred choice in various industries due to their numerous advantages over traditional materials. Their unique composition and properties cater to diverse needs, making them an optimal solution for environments requiring robust and reliable ceiling systems.

From a trustworthiness standpoint, consumer feedback and usage statistics consistently demonstrate high levels of satisfaction with FRP ceiling grids. Their reputation for excellence is built upon years of successful application in challenging environments, providing industry experts and facility managers with peace of mind. When selecting ceiling grid solutions, the reliability and proven track record of FRP materials make them an obvious choice for professionals looking for a balance of practicality and performance. Real-world applications further highlight the benefits of FRP ceiling grids. In the pharmaceutical industry, for example, the non-porous surface properties help maintain sterile environments by preventing microbial growth. Similarly, in the food industry, their resistance to fats, oils, and acids ensures that hygiene standards are upheld without frequent interventions or replacements. Facility managers and property developers often report tangible cost savings when opting for FRP ceiling grids. Not only do these materials reduce the need for frequent replacements, but they also lower the risk of unexpected expenses related to water or chemical damage. Additionally, the streamlined installation process minimizes downtime, allowing for quicker project turnarounds and reduced labor costs. Sustainability is another critical advantage of FRP ceiling grids. Compared to traditional materials such as steel or aluminum, the production of FRP imposes a smaller environmental footprint. Many manufacturers prioritize eco-friendly practices, utilizing recycled materials and reducing waste throughout the production cycle. This sustainable approach aligns with corporate and social responsibility goals, offering businesses an environmentally conscious building solution. In summary, FRP ceiling grids are a modern, efficient, and reliable solution for any environment requiring a sturdy and flexible ceiling system. Combining durability, aesthetic versatility, ease of installation, and sustainability, they stand out as a superior choice in today’s dynamic and demanding construction landscape. The integration of FRP ceiling grids is a testament to innovation in materials engineering, providing lasting benefits that meet the high standards of 21st-century architecture and facility management.

From a trustworthiness standpoint, consumer feedback and usage statistics consistently demonstrate high levels of satisfaction with FRP ceiling grids. Their reputation for excellence is built upon years of successful application in challenging environments, providing industry experts and facility managers with peace of mind. When selecting ceiling grid solutions, the reliability and proven track record of FRP materials make them an obvious choice for professionals looking for a balance of practicality and performance. Real-world applications further highlight the benefits of FRP ceiling grids. In the pharmaceutical industry, for example, the non-porous surface properties help maintain sterile environments by preventing microbial growth. Similarly, in the food industry, their resistance to fats, oils, and acids ensures that hygiene standards are upheld without frequent interventions or replacements. Facility managers and property developers often report tangible cost savings when opting for FRP ceiling grids. Not only do these materials reduce the need for frequent replacements, but they also lower the risk of unexpected expenses related to water or chemical damage. Additionally, the streamlined installation process minimizes downtime, allowing for quicker project turnarounds and reduced labor costs. Sustainability is another critical advantage of FRP ceiling grids. Compared to traditional materials such as steel or aluminum, the production of FRP imposes a smaller environmental footprint. Many manufacturers prioritize eco-friendly practices, utilizing recycled materials and reducing waste throughout the production cycle. This sustainable approach aligns with corporate and social responsibility goals, offering businesses an environmentally conscious building solution. In summary, FRP ceiling grids are a modern, efficient, and reliable solution for any environment requiring a sturdy and flexible ceiling system. Combining durability, aesthetic versatility, ease of installation, and sustainability, they stand out as a superior choice in today’s dynamic and demanding construction landscape. The integration of FRP ceiling grids is a testament to innovation in materials engineering, providing lasting benefits that meet the high standards of 21st-century architecture and facility management.

Next:

Latest news

-

Revolutionizing Interior Design with Ceilings t grid Suspended SystemNewsOct.29,2024

-

Revolutionizing Ceiling Design with ceiling access panel with Gypsum Tile WaterproofNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High quality Mineral Fiber Ceiling TilesNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High-Quality Mineral Fiber Ceiling Tiles: A Comprehensive GuideNewsOct.29,2024