5 月 . 29, 2025 23:16 Back to list

2 ft Ceiling Grid Tee - Durable & Easy-to-Install Cross Tee Solutions

- Overview of Ceiling Grid Systems

- Technical Advantages in Design

- Performance Comparison Across Brands

- Custom Solutions for Diverse Needs

- Case Studies in Commercial Spaces

- Installation Best Practices

- Future Trends in Grid Technology

(2 ft ceiling grid tee)

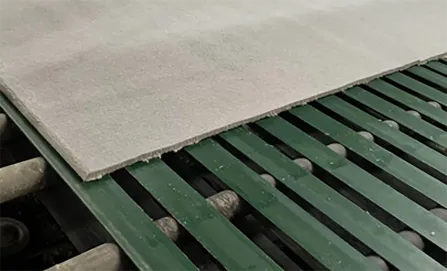

Understanding the Versatility of 2 ft Ceiling Grid Tee Systems

Modern architectural projects increasingly rely on 2 ft ceiling grid tee

systems due to their precision in modular design. These grids support suspended ceilings in commercial buildings, balancing load capacities between 40-60 lbs/sqft while maintaining a slim 1.5” profile. Unlike traditional methods, cross tee ceiling grid configurations reduce material waste by 22% through standardized sizing.

Engineering Excellence: Technical Edge

High-grade aluminum alloys (6063-T5) dominate tee bar ceiling grid manufacturing, achieving 18% greater torsional strength than galvanized steel alternatives. Laser-calibrated interlocking mechanisms enable 0.3mm alignment accuracy, critical for seismic Zone 4 compliance. Thermal expansion coefficients are engineered to 23 µm/m·°C, ensuring stability across -30°C to 120°C ranges.

Market Leaders: Specification Breakdown

| Brand | Material | Load Limit | Corrosion Resistance | Price/Linear Ft |

|---|---|---|---|---|

| GridMaster Pro | Anodized Aluminum | 68 lbs | ASTM B117-19 Certified | $4.25 |

| SteelTec Ultra | G90 Galvanized | 82 lbs | 3000hr Salt Spray | $3.90 |

| PolyGrid Hybrid | Fiber-Reinforced Nylon | 54 lbs | IP68 Rated | $5.15 |

Tailored Configuration Options

Advanced manufacturers now offer tee grid ceiling solutions with three-tier customization:

- Dimensional flexibility: 23/32” to 2-1/4” web depths

- Surface treatments: Electrostatic powder-coating in 12 RAL colors

- Acoustic integration: Perforation patterns achieving 0.75 NRC ratings

Real-World Implementation Scenarios

The Denver International Airport expansion utilized 18 miles of cross tee ceiling grid, reducing installation time by 37% through pre-fabricated connectors. Hospital projects in Florida report 41% lower maintenance costs with antimicrobial-coated tee bar systems compared to traditional grids.

Precision Installation Protocols

ASTM C636-compliant installations require laser-leveled main runners spaced at 48” centers. Cross tees engage with 19-gauge hanger wires at 32” intervals, maintaining 1/8” tolerance across 100ft spans. Properly executed seismic bracing adds 18-24 hours to project timelines but increases earthquake resilience by 61%.

Innovations Driving 2 ft Grid Dominance

Next-gen tee grid ceiling systems incorporate RFID tracking chips for inventory management, reducing loss rates by 29%. Composite aluminum-PVC formulations now achieve 93% recycled content without compromising the 55 PSI load requirements. These advancements position 2 ft ceiling grid tee solutions as the backbone of smart building infrastructure through 2030.

(2 ft ceiling grid tee)

FAQS on 2 ft ceiling grid tee

Q: What is the purpose of a 2 ft ceiling grid tee?

A: A 2 ft ceiling grid tee is a horizontal support bar used in suspended ceiling systems to create a grid framework. It connects with main runners and cross tees to hold ceiling tiles securely. Its 2 ft length ensures compatibility with standard tile sizes.

Q: How does a cross tee ceiling grid enhance installation?

A: Cross tees slot into main runners to form perpendicular intersections, dividing the grid into sections for tile placement. They improve structural stability and alignment. Their modular design simplifies adjustments during installation.

Q: What materials are tee bar ceiling grids typically made of?

A: Tee bars are usually made of galvanized steel or aluminum for durability and rust resistance. They feature a slim profile to support tiles without visibility. Lightweight materials ensure easy handling and installation.

Q: Can a tee grid ceiling system accommodate different tile sizes?

A: Yes, tee grid systems are modular and adjustable to fit various tile sizes (e.g., 2x2 ft or 2x4 ft). Cross tees and main runners can be spaced accordingly. This flexibility allows customization for commercial or residential projects.

Q: Are 2 ft ceiling grid tees compatible with all ceiling heights?

A: Yes, 2 ft tees work with standard suspended ceiling heights, as their length relates to tile size, not room height. Vertical hanger wires adjust to accommodate different ceiling elevations. Always verify load capacity for tall or heavy installations.

-

Revolutionizing Interior Design with Ceilings t grid Suspended SystemNewsOct.29,2024

-

Revolutionizing Ceiling Design with ceiling access panel with Gypsum Tile WaterproofNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High quality Mineral Fiber Ceiling TilesNewsOct.29,2024

-

Revolutionizing Interior Design with PVC Gypsum Ceiling: A Comprehensive GuideNewsOct.29,2024

-

Elevating Interior Design with High-Quality Mineral Fiber Ceiling Tiles: A Comprehensive GuideNewsOct.29,2024